- Outstanding processability of the tubes for effervescent tablets on all common filling systems & lines

- Machines according to current standards allow us to produce the plastic tubes of the highest quality quickly and smoothly

- IML technology and HD offset printing for the desired decoration of your effervescent tablet tubes

- With the Sanner desiccant closures, we supply a safe complete packaging for effervescent tablets

Outstanding processability of the tubes for effervescent tablets on all common filling systems

Our plastic tubes for effervescent tablets have been tested by all established filling machine manufacturers and found to be very good. Looking for references?

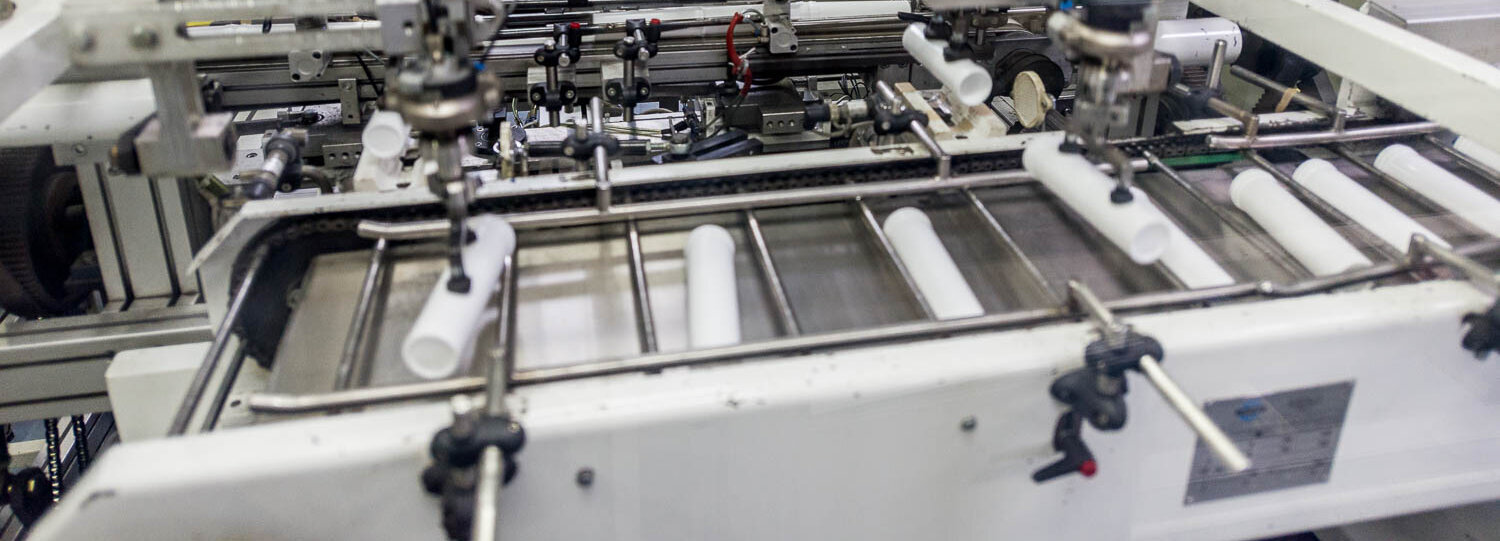

Machines according to current standards allow us to produce the plastic tubes of the highest quality quickly and smoothly

A fully integrated process from raw material delivery to processing with the most modern control and monitoring systems guarantees hygienic and high-performance production of the tubes for effervescent tablets and meets all

guidelines of the pharmaceutical and consumer health care industry, such as the European regulations 1935/2004/EG and 10/ 2011/EC. You will receive your tubes set, packaged upside down or in bulk.

HD offset printing for the desired decoration of your effervescent tablet tubes

- Benefit from our many years of know-how in printing of plastic tubes in large quantities

- We produce in high-speed processes with high printing speeds

- We can display all color variations and nuances on all tube sizes with up to 8 colors in off-set printing HD (letterset), including special colors according to Pantone

- Especially the off-set printing HD (letterset) provides efficiency advantages with large lot sizes

- Only use low-migration paints and varnishes that meet international food standards for your packaging for effervescent tablets

The Sanner Brilliance® Tube convinces with tubes for effervescent tablets in IML technology

Stand out from the crowd with your effervescent tablet packaging design. Make it easier for your customers to recognize you at the point of sale and thus create more brand identification:

- Photorealistic printing for more attention and value

- Different surface structures and peel-off labels

- Price-optimized CMYK printing with up to 8 colors and metallic effects

- Good legibility with small font size, thus more information on the same area

By offering both decoration techniques for packaging for effervescent tablets, we offer our customers the greatest possible flexibility with different print runs. Of course, our service also includes the complete processing of print data management.

You are not sure whether to use Offset HD or IML Technology for packaging for effervescent tablets?

Here you get a direct comparison and overview:

Download Flyer Offset printing Download Flyer In-Mould-Labeling-Printing

IML technology for Sanner effervescent tablet tubes

With the Sanner desiccant closures, we supply a secure system for packaging for effervescent tablets

Moisture penetrating the packaging can cause effervescent tablets, tablets, coated tablets and film-coated tablets to dissolve prematurely, lose their color or effectiveness or even develop undesirable odors.

Therefore, use the appropriate desiccant closures from Sanner for our plastic tubes for effervescent tablets and you will receive an efficient system, an ideal

climate in your packaging and the well-known Sanner Atmo Guard System® product protection. Our products are characterized by a high level of tightness, with which little moisture penetrates (low WVTR), this is then adsorbed by the desiccants integrated in the closure. We are happy to inform you about our leak test methods.