Sanner offers a wide variety of desiccant capsules, also available as click-in solutions or particularly effective desiccant canisters from the Sanner AdCap® series.

The new generation of desiccant capsules - Sanner AdCap®

The innovative design of AdCap® combines the advantages of both conventional desiccant capsules and desiccant canisters into a single product. Our desiccant capsules ensure that moisture or odors are optimally adsorbed immediately after filling. And it doesn't matter where the AdCap® desiccant capsule is located inside the product container thanks to its integrated cardboard disc and the lattice structure within the canister wall. AdCap® desiccant capsules are your 360-degree moisture absorber.

High adsorption desiccation and easy processing properties for safe and efficient moisture control

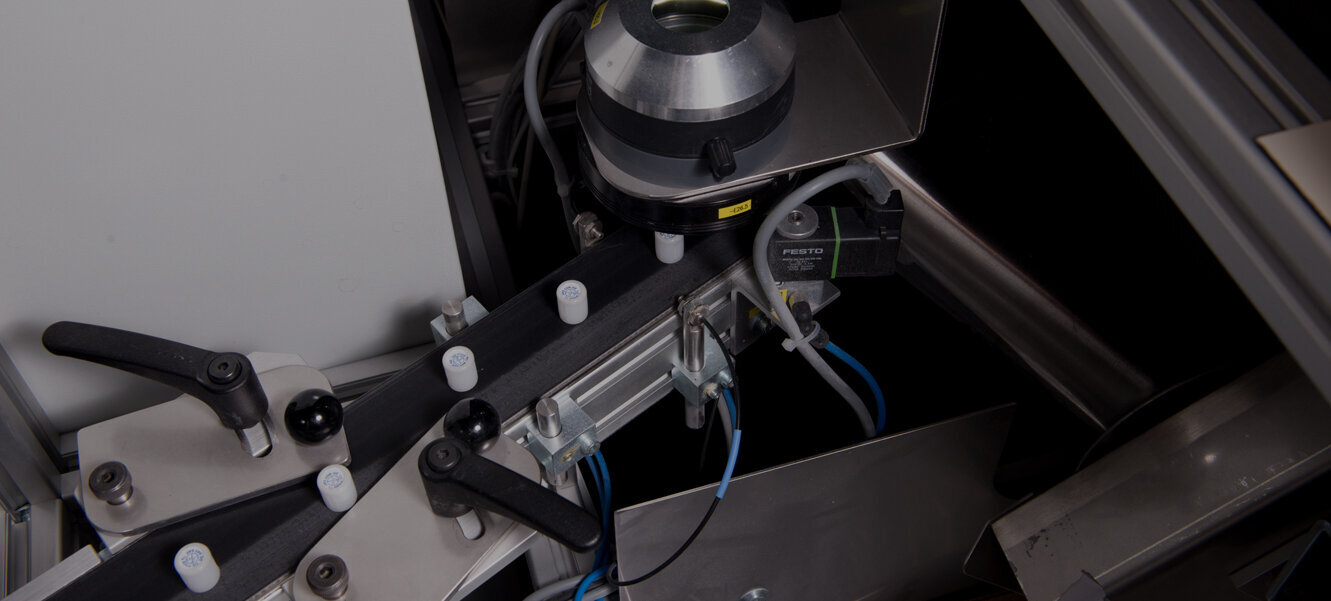

- Filling process speeds of 300 to 600 pieces per minute thanks to the cylindrical and flat shape on all standard filling systems

- High pressure stability compared to conventional desiccant canisters

- Reduced risk of unwanted intake thanks to the unique canister lattice structure

- No dust formation thanks to filling with spherical silica gel (SG) and molecular sieve (MS) desiccant materials

- Easier desiccant identification with type and weight printed on the cardboard disc

- All materials used in Sanner AdCap® desiccant canisters comply with relevant U.S. FDA 21 CFR and EU food safety regulations, as well as United States Pharmacopeia (USP) <661.1> and <670>. In addition, Sanner AdCap® is listed in a Type III DMF with the U.S. FDA

Sanner SG/AC desiccant capsules with activated carbon and silica gel maintain for the right atmosphere in your packaging

Combine strong moisture protection with effective odor control in a single desiccant capsule containing a mixture of silica gel desiccant and activated carbon. Our AdCap® SG/AC desiccant capsules can help to minimize unpleasant odors caused by solvent residues and organic contaminants after packaging has been opened. Sanner AdCap® SG/AC desiccant canisters or capsules can efficiently address a number of product odor challenges.

- Ideal for absorbing organic pollutants through outgassing

- Highly effective for removing traces of organics and chlorine

- Microporous desiccant materials with a large surface area

- Reduced ash content and higher purity

- Excellent mechanical hardness

We offer you an extensive portfolio of desiccant canisters in our online product catalogue

Sanner - your specialist for effective product protection in pharmaceutical packaging

Sanner offers precision injection molding of the highest quality. The innovative lattice structure of Sanner AdCap® desiccant canisters is unique and results in desiccant canisters with the maximum effectiveness in adsorbing moisture in the packaging container. Sanner desiccant canisters and capsules are extremely pressure-resistant and, thanks to their precise size and smooth surface, achieve high filling speeds on all standard filling systems with no conversion required. We have proven expertise in the filling and integration of desiccant canisters for decades.

Integrating a desiccant capsule or canister from Sanner can turn your plastic pharmaceutical plastic packaging into an effective moisture regulation and odor protection system. And that means your product is protected as well. With our desiccant focused expertise, we have the ability to maintain the required residual moisture levels in our canisters. All of our desiccated canister and capsule solutions have been tested according to the Sanner Atmo Guard System® which is part of our Advance with Agility™ program for predictive modeling for optimized product stability, custom or standard packaging solutions and unparalleled quality for efficient packaging operations.

An overview of drop-in solutions such as desiccant capsules and desiccant sachets from Sanner.