Unrivalled Desiccant Expertise

- Desiccant leadership

- Integrated desiccant solutions

- Drop-in desiccant solutions

- Shelf-Life Consultation and DFMA Approach

Sanner Desiccant Leadership

Many of today’s pharmaceutical and medical device products are moisture sensitive.

Our unique Sanner Atmo Guard System® generates real packaging moisture data and uses it to help CDMO customers select the ideal desiccant solution for their customized device design.

Sanner’s industry leading desiccant expertise is available to all CDMO customers with moisture sensitive applications.

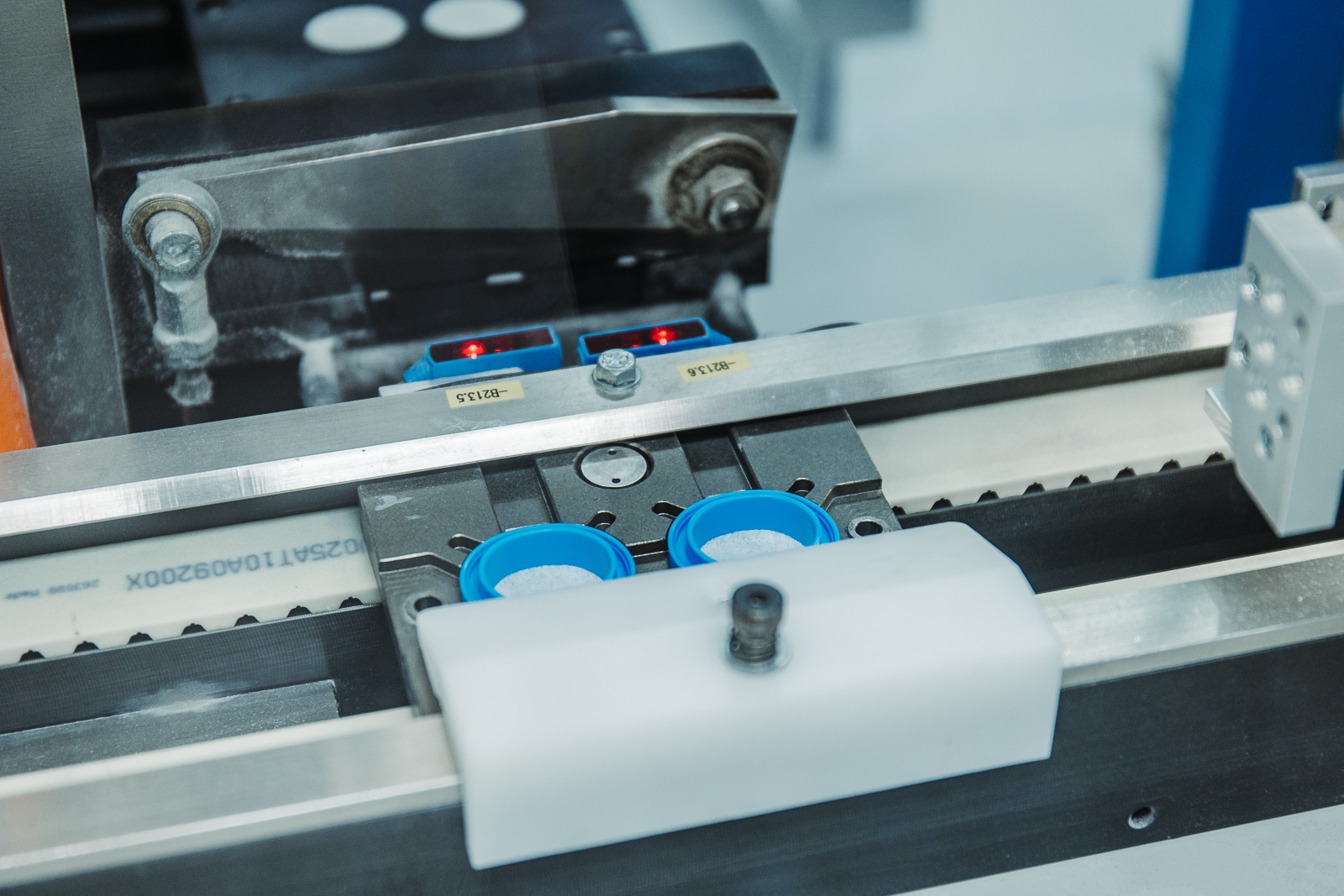

Integrated Drug-Device Combination Devices with Desiccants

Some of today’s drug or biologic substances that are intended to be delivered by a drug delivery device are moisture sensitive. Sanner’s CDMO services can incorporate their industry leading desiccant technology into the design of their complex drug-device combination product from its inception. Desiccant can also be integrated into secondary packaging designs to help maintain the reduced moisture levels required to fullfill the product’s shelf life. Combining the desiccant into the device design, in combination with creating moisture tight packaging seals to reduce the ingress of external moisture, are key factors to controlling moisture levels in packaging systems.

Drop-in Desiccants

Sanner manufactures a full range of desiccant options for traditional pharmaceutical packaging applications. These can include desiccant drop-in canisters or pouches that are tested and safe for use with pharmaceutical products, drug delivery, diagnostic and medtech devices. Our desiccant drop-in solutions can be utilized for moisture control with a range of devices such as inhalers or point of care rapid tests.

Shelf-Life Consultation and DFMA Approach

Sanner has formalized its device development best practices with our defined stage gate Idea-Design-Product (IDP) Process®. Combining the Sanner Atmo Guard System® with the Sanner IDP Process® you not only get the ideal product protection but also a Design for Manufacturing and Assembly (DFMA) design concept. We take a holistic approach to determining the optimal desiccant solution for CDMO customer products. We assess individual desiccant requirements and conduct a shelf-life consultation before advancing the scalable solution to implementation and ultimately serialization. Our desiccant solutions can typically be easily separated from the device after use, enabling enhanced recyclability of the device in standard recycling processes.

Sanner CDMO Desiccant Solutions

Sanner can provide complete moisture control solutions through a range of industry leading desiccant technology options. With integrated and drop-in desiccant options, Sanner has a proven record of providing reliable desiccant solutions that are compliant with pharmaceutical and medical device regulations while being cost-efficient for the customer. If you would like to learn more moisture adsorption and the behaviour of silica gel or molecular sieve, please see Sanner FAQs on desiccants.