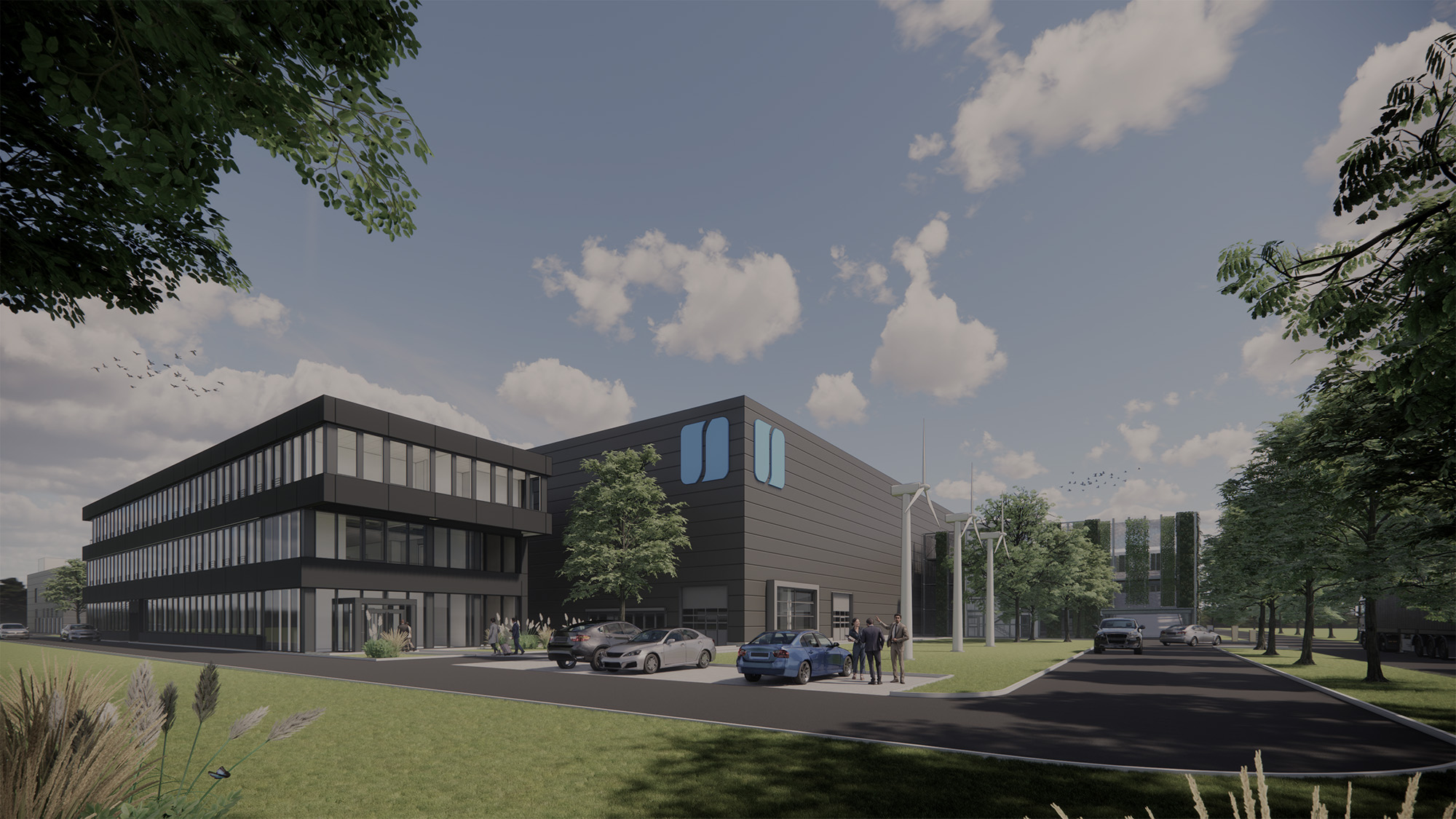

Grounbreaking ceremony

With the ground-breaking ceremony for the new production site in Bensheim, the Sanner Group is preparing for further growth. The focus is on the continuous further development of the packaging and desiccant portfolio for the healthcare sector as well as the expansion of activities as a device CDMO with more capacity for fully automated production and assembly of medical technology, diagnostics and pharma drug delivery solutions. More than 120 participants from politics and management as well as shareholders, companies involved in the construction, the Sanner project team and the workforce attended the official groundbreaking ceremony on January 21 and the subsequent celebrations at the new location in the "Stubenwald" industrial park in Bensheim. Now the construction has started, all production is scheduled to move to the new, state-of-the-art factory from September 2024 on. This scores with its central location and good motorway connections. The new location will be a great place to work with sufficient capacity to meet all the needs of our current and future customers.

Establishment of clean room production

Many devices for highly sensitive application areas need cleanroom production with environmental conditions in which the airborne particle concentration should not exceed specific limits. At the new site, we offer a large cleanroom environment dedicated specifically to ISO Class 8 production (optional Class 7)for injection molding and assembly. Our dedicated professionals have specialized expertise in cleanroom production and are trained to operate the environment safely and efficiently. With our new clean room production, Sanner is ready for even more CDMO projects that require working in such environment.

Start of construction

The new location will be placed on 30,000 square meters and will thus double Sanner's existing capacities in Germany. New state-of-the-art, highly automated manufacturing equipment will make this possible. The new factory will have the following features:

• 300 square meters for a new technology and innovation center ("Sanner Technikum"), in which customer-specific solutions and prototypes are developed,

• separate areas for desiccant and injection molding,

• a flexible injection molding and assembly hall that can be flexibly adapted to customer needs in both the packaging and device CDMO areas,

• an automated central material supply for loading all machines,

• Class 8 clean room capacities,

• ESD floors for the assembly of electronic medical technology components

• Doubling of the current storage capacity with a later established fully automated warehouse management system.

Sanner would like to offer its customers maximum flexibility and automation. The new production facility offers enough space to cover all needs - from desiccant and effervescent tablet packaging to medical technology, diagnostics and pharma drug delivery solutions.

Together with many trees in the green area and a green roof, these measures make the new location a prime example of sustainable production in the region.

Construction of production & logistic hall

With the casting of the base plate, Sanner is laying the foundation for a solid base and, above all, the cornerstone for even more sustainability: Did you know? The new production facility will reduce energy consumption by 20 to 30 percent. By reducing natural gas consumption and using the latest heat pumps and an automated heat exchange system, Sanner will continue to improve its ecological footprint. A photovoltaic system will also be installed. It will cover the entire roof of the factory and generate enough energy to power over 300 single-family homes. In addition, wind turbines provide the energy needed for outdoor lighting and chargers for electric bicycles and cars. Together with many trees and a green roof, these measures make the new location a prime example of sustainable production in the region.

Relocation

From September 2024, the Sanner Group will relocate its production site in Germany to a new location within Bensheim. The new, state-of-the-art production facility is currently under construction and will have more than double the production capacity in the future with sufficient potential for the reliable supply of your needs as well as room for expansion for future projects. The new building is of course included in the certification routine / certification according to ISO 9001 / ISO 15378 / ISO 13485 / BRCGS

• The relocation of the plants is accompanied by a comprehensive risk assessment

• The production systems are qualified in close cooperation with you according to the agreed requirements

• We expect to offer tours of the new production environment from 2025 onwards.

If you have any questions about this and/or the new building and relocation, either now or in the coming months, please send them to newfacility@sanner-group.com. Your request will be clarified internally as quickly as possible with the relevant contact persons and a timely response will be ensured.

Building of automated logistics

Sanner credo is customer service. This is proved by an OTIF level of >98%. With this new facility we would like to keep this service level and even improve in-house transportation of raw materials, semi-finished and finished products between the different workstations and finally in the logistics area. Each stage is extremely important because it contributes to the smooth movement of goods along the value chain and so, the new state-of-the-art facility will come with an fully-automated in-house logistics to handle your products even safer and quicker.

Start of production

Machines and production equipment leave Bensheim-Auerbach after almost 130 years. Off to new waters in the Stubenwald II industrial park in Bensheim. An old chapter closes, what remains are completely new design and modernization options for the citizens of Auerbach at the old location & on the other side a development and manufacturing organization that is constantly developing into a big player in the pharmaceutical and medtech supplier area.

Project description

After almost 130 years in Bensheim-Auerbach, the Sanner Group will move its production site in Germany to a new location within Bensheim from September 2024. The new address will be Bertha-Benz-Strasse 9 in Bensheim. The new, state-of-the-art production facility, including the new administration building, is currently under construction and will have more than twice the production capacity in the future, providing sufficient potential for the reliable supply of your needs and room for expansion for future projects.

Our construction site from above

Take a look at the current construction progress from above, taken by a drone that flies over the emerging HQ regullary.

Live-Webcam

Keep the construction site in an eye, 24/7, regardless any weather conditions.

To the webcam