How quickly are you resolving moisture management problems in your healthcare products?

For over 75 years, Sanner has provided desiccated packaging for optimized drug, diagnostic & nutraceutical product stability.

As a proven, global supplier-consultant to these industries, we offer unparalleled product quality coupled with a reliable supply chain of drop-in and built-in moisture management solutions to quickly resolve chemical and physical stability problems.

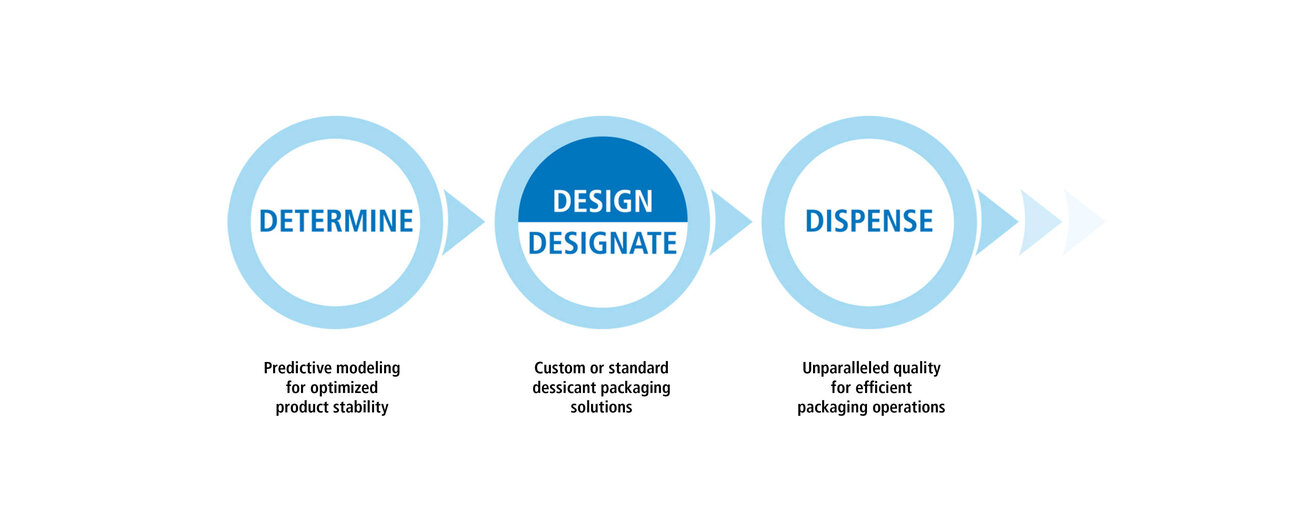

The Advance with Agility™ program can provide you with faster development, packaging selection or changes, and overall time to market by combining:

DETERMINE

- Fast predictive stability/shelf-life modeling of your product

DESIGN | DESIGNATE

- Sanner custom or standard desiccant packaging

DISPENSE

- Turnkey, efficient packaging operations during which desiccant capacity is preserved.

Determine

Predictive Moisture Management Modeling for Optimized Product Stability & Shelf-Life

Sanner’s Quality by Design (QbD)-based Atmo Guard System® programs, quickly predict moisture management outcomes for a wide range of pharmaceutical, nutraceutical, and diagnostic products in primary packaging and medical devices that promote their physical and chemical stabilities.

Atmo Guard System®

The Sanner Atmo Guard System®coordinates the use of ASAPprime®, the industry standard for accelerated pharmaceutical stability modeling, which allows to:

- Quickly determine the moisture management profile required for product stability in primary packaging

- Eliminate time consuming and expensive packaging accelerated stability studies saving time and money

- Reduce development time

Save up to 12 months in time to market

“SANNER’S COMPREHENSIVE KNOWLEDGE OF DRUG PRODUCT FORMULATIONS AND MOISTURE MANAGEMENT TECHNOLOGY IN PRIMARY PACKAGING ALLOWED US TO QUICKLY RESOLVE STABILITY CONCERNS.”

– Major Branded Pharmaceutical Company Customer

Designate

Drop-in/Built-in Moisture & Odor Management Solutions That Meet Virtually Any Requirement

Sanner drop-in and built-in moisture management solutions are individually tailored to meet the specific shelf-life requirements of all your moisture-sensitive drug products and drug delivery devices. These product stability enhancing solutions are provided with Sanner’s extensive regulatory support and available equivalency data (as required). Sanner Moisture Management programs are designed to be scalable and easily implemented with current processing equipment from the start, so that operational implementation doesn’t delay the critical commercialization step that ultimately brings your product to market.

Never be sole sourced again with Sanner.

Design

Customized Packaging Development for Moisture Management & Stability

Packaging integrity and the mitigation of moisture ingress risks are critical to achieving product shelf-life stability. The Sanner Idea-Design-Product (IDP) Process® combines our integrated primary pharmaceutical packaging and drug delivery device development programs, with our Atmo Guard moisture management system into a single efficient process.

Sanner IDP

For new or currently marketed drug products, the Sanner Idea-Design-Product (IDP) Process can deliver product stability solutions through industry-leading custom primary packaging presentations with built-in desiccant packaging options that provide customers with unique market differentiation and growth opportunities.

And all from a single source.

Dispense

Unparalleled Quality with Efficient Packaging Operations

Sanner’s exclusive Adsorption Assurance (AdSure™) program provides customers with the guidance they need to seamlessly incorporate moisture management through desiccant packaging in their commercial packaging operations. At Sanner, we don’t just design moisture management for our customer’s products, we provide the direct support and expertise needed to make it reality on the production line.

AdSure™

AdSure™ programs are designed to ensure that desiccant capacity protection occurs during commercial packaging operations. The physical and chemical stability profiles of every product are maintained throughout the product’s lifecycle by the application of just the right drop-in desiccant, moisture regulators and odor absorbers with their selected primary packaging system.

- Expert Guidance - Sanner provides related packaging, handling, use, protection, and dispensing guidance for the validation of customer commercial packaging operations to ensure the selected desiccants perform.

- Easy Implementation is Built-In - Sanner’s built-in solutions are easily implemented on standard bottling line machinery with direct support available

- Simple Drop-In Solutions – Sanner’s AdPack® packet and AdCap® canister moisture management drop-in solutions can be easily implemented on your new or existing commercially available dispensing machinery

Sanner Delivers Optimized Packaging Uptime.

Sanner is your collaborative partner for moisture management and desiccated packaging solutions. We will work cooperatively with your preferred packaging machinery supplier to create operational equipment and procedure plans that incorporate the dry-air purge requirements needed for the successful implementation of our drop-in and built-in desiccant packaging solutions.

Sanner Advance with Agility™

Faster development, packaging changes & time to market