Quality Driven CDMO Services

- Quality Management System

- State of the art Metrology systems

- Integrating ISO Standards

- In-Process Control

Quality Management System (QMS)

Sanner’s Quality Management System (QMS) is designed to ensure that we manufacture products to the appropriate requirements. It ensures that every time a process is performed, the same information, methods, skills and controls are used and applied in a consistent manner. Our Quality Management System (QMS) enables our teams to better deliver on their commitment to continually developing products for the benefit of our customers.

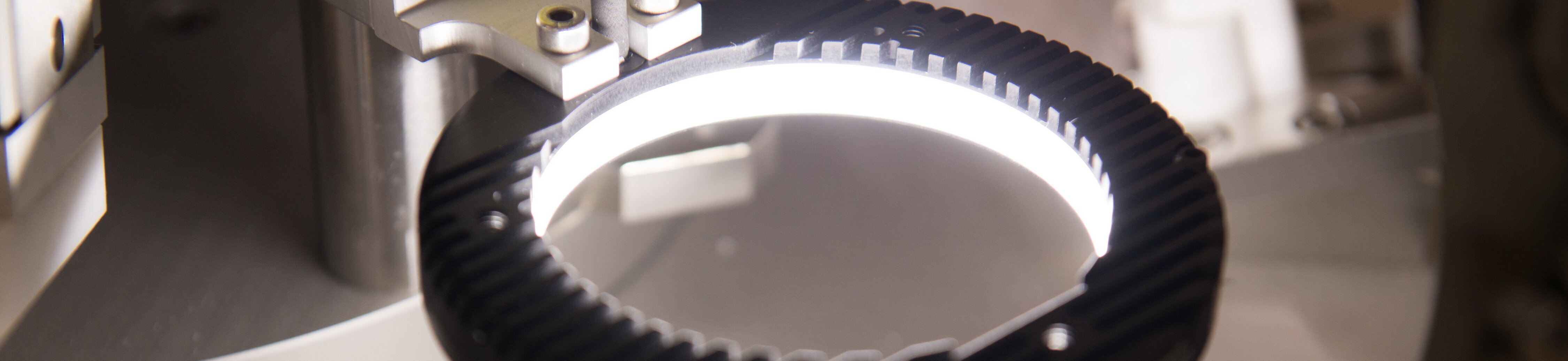

State of the Art Metrology Systems

Quality Control (QC) is measured utilizing metrology systems in manufacturing settings. These systems of measuring numerous parameters is a critical function when manufacturing products for the highly-regulated medical device and pharmaceutical sectors. Sanner’s CDMO services employ a wide range of metrology tests and measures to ensure quality of critical steps of the manufacturing process. We use semi- and fully-automated tactile and optical measuring systems, along with microscope and profile projector measuring to confirm the material properties of the devices and components. Sanner performs incoming inspections of raw materials to make sure they meet requirement specifications before they go into manufacturing. With the vast array of potential testing that can be performed, our metrology group builds quality into all our processes and products.

ISO Standards

Sanner adheres to applicable ISO requirements at its state-of-the-art sites in Asia and Europe. All facilities work under GMP-compliant conditions and achieve 100% traceability through our Manufacturing Execution (ME) system. These make Sanner a better CDMO, able to demonstrates its focus on meeting the highest quality standards in everything we do. Across our network, our QMS is designed to ensure that facilities meet the following ISO standards that are appropriate for their business needs:

- ISO 9001 - Quality Management Systems (QMS) General

- ISO 13485 – Quality Management Systems (QMS) Medical Devices

- ISO 15378 – Primary Packaging Materials for Pharma

- ISO 50001 – Energy Management

- BRCGS Certificate – global food safety standard

In-Process Controls QC

Sanner has invested in the latest in-process control technologies which allow our network of manufacturing sites to successfully deliver quality products to our customers. We operate assembly lines with 100% in-process camera and video control systems that monitor products for compliance with critical quality aspects of their specifications. Sanner’s validated Computer-Aided Quality (CAQ) software helps operations maintain and document quality during production processes as part of Sanner’s Quality Management Systems (QMS). We utilize weigh cells for even the smallest filling volumes. Sanner institutes quality checks for CDMO customer devices including in-process weld tests, part measurement, and metal detection to ensure product quality.

Sanner is Quality Driven

Sanner has a wide range of tests and technologies at its disposal, which can be utilized as part of the Quality Management System (QMS). Our Quality Management Systems (QMS) ensure that Sanner’s goods and services are compliant with the quality requirements of our customers through in-process monitoring and offline metrology systems. We are committed to quality in everything we do, in order to meet our core objective of delivering only the highest quality drug delivery, medtech and diagnostic devices to our CDMO customers, every time.

Customer information & ISO certificates