Sanner CDMO Device Molding & Tooling Services

- High-precision fully-electric thermoplastic injection molding

- Micro-injection molding

- Cleanroom molding

- Wide range of plastic materials

- 2K injection molding

- In-house mold conceptualization expertise / inhouse tooling engineering

- Tooling Maintenance

Sanner CDMO Micro Injection Molding Services

Sanner CDMO can utilize its Babyplast micro-injection molding for prototypes, pilot series parts, providing material integrity even with small shot weights (0.1g).

The Babyplast can also be operated under ISO Class 7 clean room conditions. Furthermore it is also possible to produce LSR parts in the prototype and Scale-up stage.

High-Precision Fully-Electric Thermoplastic Injection Molding

Our high-precision electric thermoplastic injection molding capabilities are designed to produce molded parts with shot weight accuracy and repeatability at low deviation to mean ratios for high-quality drug delivery, diagnostic, or medtech components.

Our high-precision electric thermoplastic manufacturing capabilities deliver robust production with consistent quality output for virtually any product volume. Additionally, Sanner offers blow molding services at a number of its facilities.

Cleanroom Molding Capabilities

Using fully automatic and robot-supported cleanroom production with minimal bioburden, Sanner can produce a range of devices for drug delivery and diagnostic applications. Sanner offers its CDMO customers molding activities in ISO Class 7 or 8 cleanrooms.

Our cleanroom molding facilities are capable of manufacturing packaging systems such as complex resealable pipettes, with pre-determined breaking points for dose opening, and thin-wall injection molded parts with exact wall thickness for tight device seals.

Wide Range of Plastic Materials

Sanner’s device CDMO teams bring extensive experience in processing a wide range of materials for different applications. Molded materials commonly utilized at Sanner include polypropylene (PP), high-density polyethylene (HDPE), all types of engineering plastics -, and various biobased materials with up to 64 cavities. Don’t hesitate to inquire if your device requires specialized materials.

2K injection molding

Sanner offers 2K injection molding capabilities that is ideal for even the most complex molded parts. Sometimes called double injection, multi-material, or two shot molding, it is a specialized molding process that combines different thermoplastics (TP) in a single molding step. 2K molding can produce your complex drug delivery, diagnostic or medtech device parts for better handling characteristics and improved user-convenience.

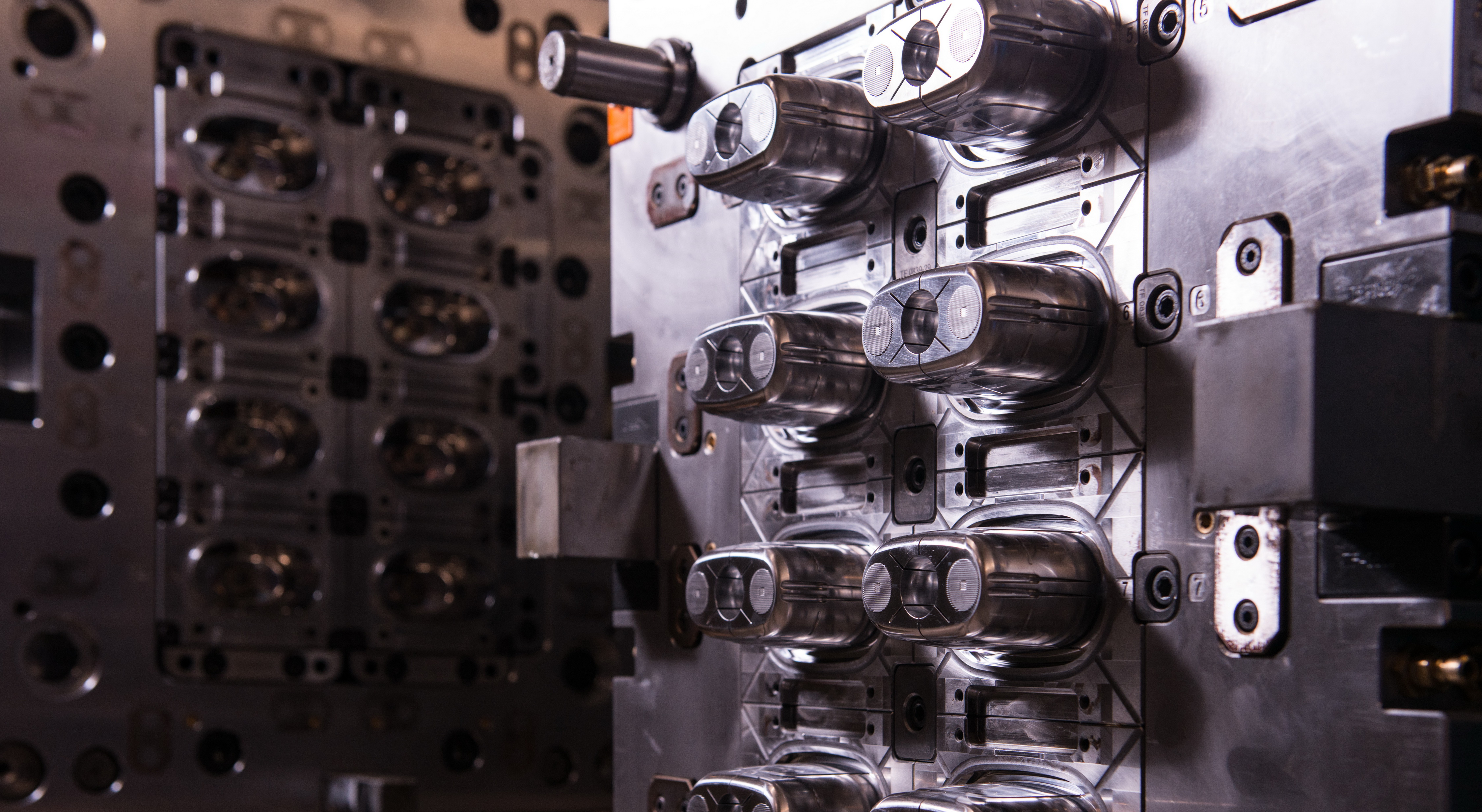

In-House Mold Engineering and Support Capabilities

Sanner takes a scientific approach to designing, developing, and maintaining molds. Sanner’s tooling engineers can design, develop and maintain tooling for even the most complex devices or components. We start with our rigorous tool concepting process followed by mold flow simulation studies to assess material fill data. This data set allows our injection molding designers can better position mold gates, anticipate knit line locations and identify difficult to fill spots within the molds early in the process. All of this is done under the oversight of our metrology group to support component quality all the way through production. Critically, Sanner maintains its molding expertise in-house, with our own tool shop for more control and quicker turnaround in mold development and maintenance. Through scientific injection molding data analysis, Sanner‘s molding processes result in high-quality reproducible parts made by validated processes for CDMO customers.

Sanner CDMO Service

Sanner’s mold tooling providers include some the world’s most advanced and well-established sources that can support virtually any tooling need. Sanner has been serving drug delivery, diagnostics, and medtech customers for over two decades with production processes and quality systems that are fully adapted to the requirements of the pharmaceutical and medical device industries. This includes our extensive injection molding capabilities from concept, design up to tool maintenance and optimization. We use our ISO Class 7 or 8 cleanrooms as well as unclassified spaces for molding activities, depending on the individual requirements, all operated under an ISO 13485 quality management system (QMS).