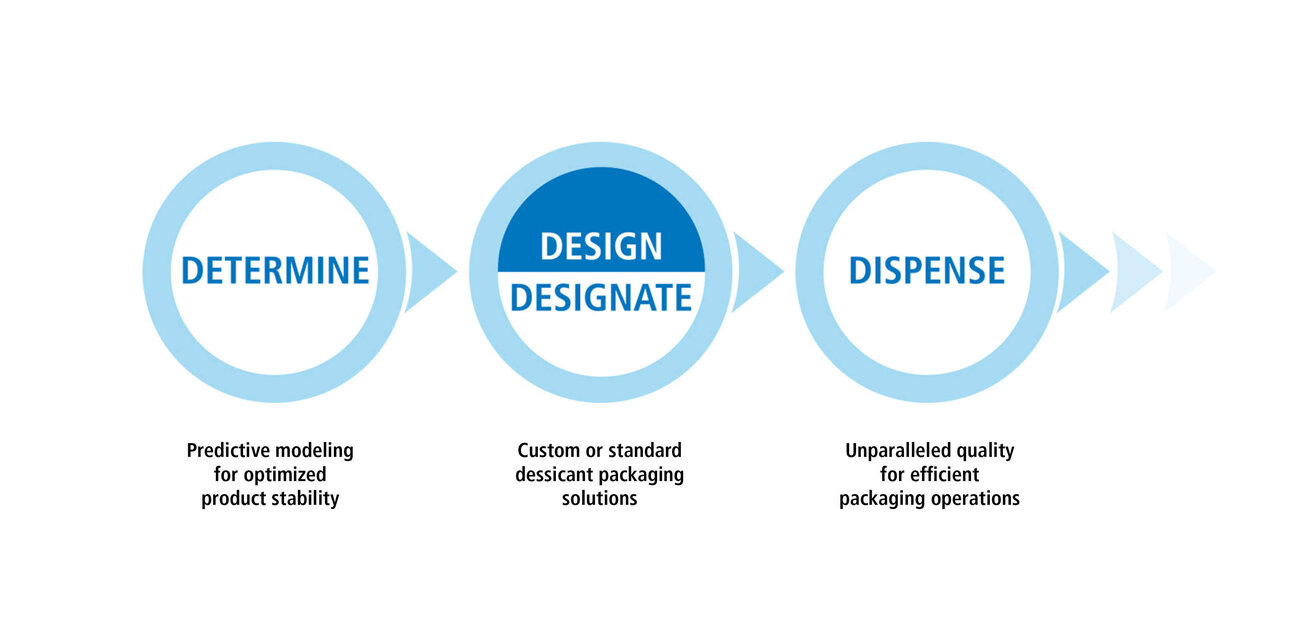

Sanner’s Quality by Design (QbD)-based Atmo Guard System® program can quickly predict moisture management outcomes of pharmaceutical, nutraceutical, and diagnostic products in primary packaging to promote their chemical and physical stability.

Optimized product stability & shelf-life

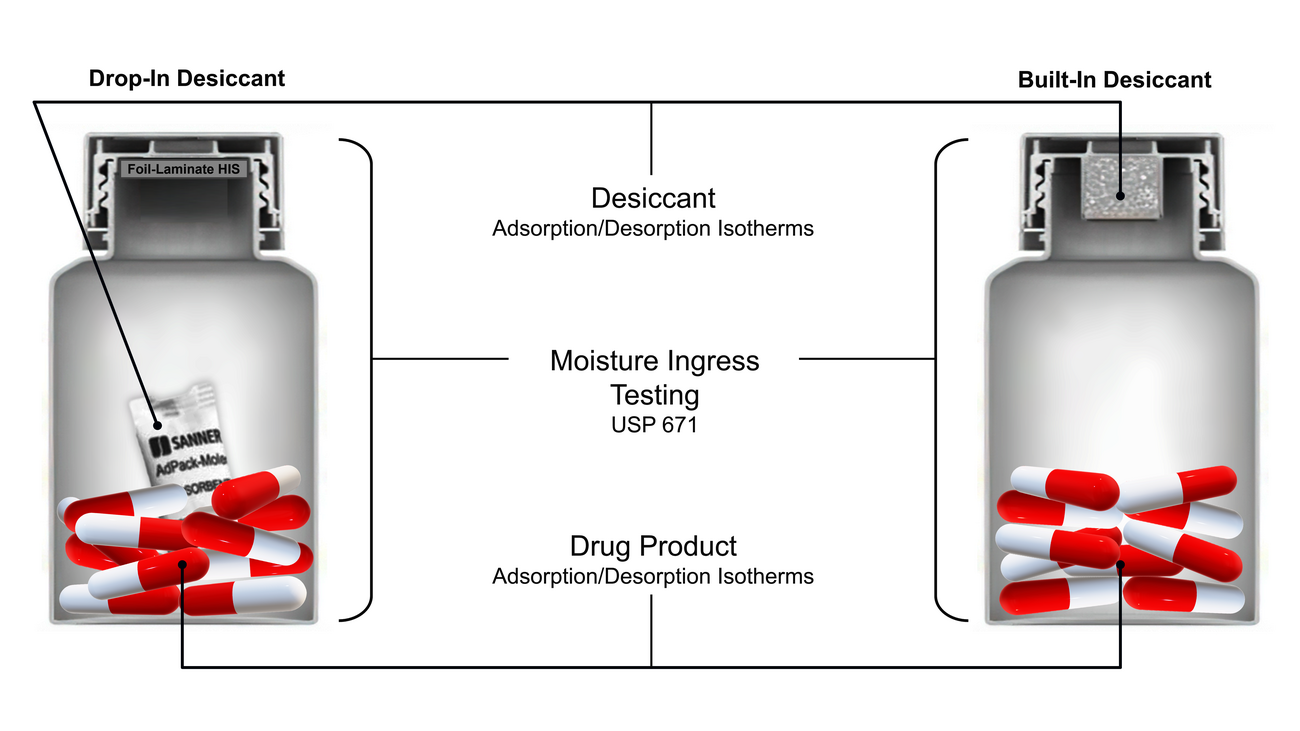

The Sanner Atmo Guard System for desiccated packaging integrates the following parameters to determine an appropriate moisture management solution:

- Chemical and physical pathways of drug, nutraceutical, or diagnostic product degradation

- Free moisture in the product

- Adsorption and desorption isotherms for the product

- Adsorption and desorption isotherms for the desiccant or moisture regulator

- Moisture ingress into primary packaging

- Initial package headspace relative humidity

- Free moisture from cotton or rayon used in bottle packaging

Two ways of protecting your product

Advance with Agility™

The Atmo Guard System is part of the Advance with Agility™ program which provides for faster development, packaging changes, and time to market.

- Quickly determine the moisture management profile required for product stability in primary packaging

- Eliminate time consuming and expensive packaging accelerated stability studies saving time and money

- Reduce development time

- Save up to 12 months in time to market

Rely on experts in moisture management and desiccated packaging

Sanner is the pioneer of desiccant integration in packaging of moisture-sensitive products and devices. Sanner offers unparalleled product quality coupled with a reliable supply chain of drop-in and built-in moisture management solutions to quickly resolve chemical and physical stability problems. We integrate desiccants in a wide variety of forms and thus create an optimal climate in the packaging or maintain the functionality of the diagnostic product or device. With our decades of experience in the field of injection molding, in-house tool technology and our design for manufacturing principle, we design the products in such a way that maximum moisture protection is achieved. With the Sanner Atmo Guard System we support with predictive moisture management modeling.